Power plants across the country utilize more than four times as much water as all U.S. homes and account for 41% of total water withdrawals, according to federal data.

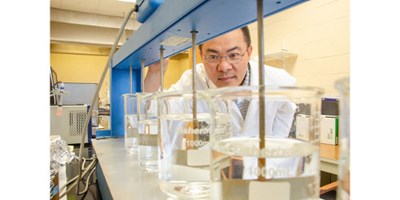

Now, with the aid of a USD400,000-Department of Energy grant, West Virginia University researchers are seeking ways to quench the thirst of the nations power plants in a more cost-effective, environmentally-friendly fashion.

The research team aims to maximize water reuse and reduce chemical and energy footprints resulting from thermoelectric generation.

At thermoelectric power plants, water is used to cool down high-temperature steam from turbines in a heat exchanger. The warm water is circulated to cooling towers to eject the heat into the atmosphere. Once the water hits the cooling tower, some of it evaporates into the air.

The plant purges this blowdown water, rife with chemicals such as calcium and magnesium that form scale on the heat exchanger surfaces, affecting heat exchange effectiveness.

Blowdown water needs to be treated or cleaned before it can be released back into the environment or reused.

The treatment is costly because of its chemical and energy requirements.